Production

Kendirliler Haddecilik, which has established all innovative and technology oriented quality systems, applies these systems individually in production processes, realizes the continuous improvement and development of its productions with the ability to respond to expectations.

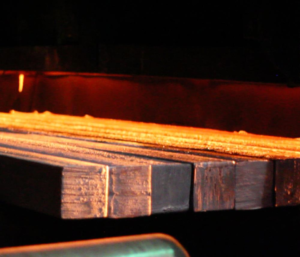

Our logs come in the dimensions of 150 x 150 x 12000, 130 x 130 x 12000, 160 x 160 x 12000, and they are cut into 6000 mm lengthwise and then separated into two. Logs are annealed in our hydraulic system furnace with 16 flameless burners in 6500mm and 2800mm dimensions.

The furnace has a processing capacity of 70 tons per hour. The logs we take to roll after annealing are passed through 13 counters to complete the rolling process. We are also producing ribbed bar iron between N8 and N32. Rolled materials are cut to a grid of 48 meters to the of 55 meters and then cut according to the desired package size (6m, 7m, 8m, 12m). Then the ready packages are labelled and sent to the stock.

Chemical and technical analysis of the products from our production are completed in our R&D department and laboratories; and then the products become ready to be shipped.

They are packed in a bundle and stacked on the stock area. Each bundle has an average weight of 2000kg. According to the orders received from the customers, the goods are shipped to their destinations.